Parameters

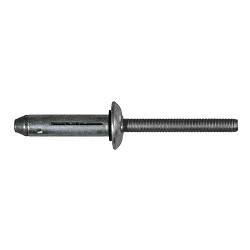

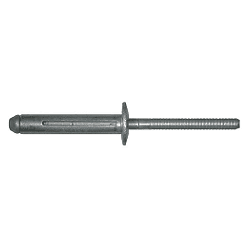

The #MBT-DT14-15 steel Bobtail Huck bolt with a 14mm diameter, flanged head, and 10-20mm grip is engineered to meet the unique challenges of a wide range of assembly applications – the Bobtail offers safe, quiet, swaged-on installation technology in an advanced Huck bolt design meant to deliver superior joining strength in even the most extreme environments.

Available in a wide range of sizes and grades, Bobtail also offers quick and easy installation, and up to 10 times the fatigue strength of conventional nuts and bolts.

Finally, when you factor in the cost of the fasteners with installation and inspection labor, Bobtail often provides an overall lower installed cost.

Benefits / Highlights

Unlike conventional nuts and bolts, which have gaps on the thread flanks even when tightened, the Bobtail Huck bolt is designed for full metal-to-metal contact around the bolt thread by the collar. When installed, the Huck Bobtail has no gaps and delivers a more secure connection, providing reliability even in the most sever environments.

- Eliminates need for secondary operations

- Ergonomically designed installation tooling

- Low overall installed cost

- No pintail

- No repetitive stress injuries

- No special training or skills required for installation personnel

- Quick visual inspection is all that’s needed for a quality-assured joint

- Silent installation

- Superior strength (fatigue)

- Unmatched installation speed

- Vibration resistance

Unmatched Installation Speed

The Bobtail System delivers a lightening-quick installation cycle time for greater productivity – as fast as two seconds* – due, in part, to the short time required to apply the tool to the pin and initiate the installation cycle. Once the operator engages the trigger, the swage and eject sequence is programmed to complete the cycle without any additional operator input.

* Based on a typical installation of a 5/8″ Grade 8 fastener

Secure, Fast Installation

Combining an advanced fastener design with the latest in easy-to-use, ergonomic installation tooling, the BobTail system delivers a strong connection and sets a new standard for ease of installation.

- Pintail-less design means reduced noise, no waste, and improved corrossion-resistance

- Visual evidence of successful installation provided by installation indicator

- Collar material swaged into the lockgrooves forming a permanent, vibration-resistant connection

- Low-swage technology allows for faster, lighter tooling with parts that last longer

For Oversized Holes: To optimize clamp, hardened washers such as ASTM F436, DIN 6916 or EN 14399-6 are recommended for use with oversize holes and slots, along with good bolting practice.